All healthcare service providers have this in common: they want to provide sublime services to their customers while getting the most out of their investment. But to achieve this goal, it is essential for hospitals to actively manage their assets, ensuring they are always in the best operational condition. When we say assets in this context, we mean the wide variety of medical equipment used in the prevention, diagnosis, treatment, and monitoring of diseases.

With various equipment used for different purposes lying around, the hospitals need a reliable maintenance program regardless of their size, otherwise, ensuring equipment are always in the best conditions to offer predictable services to patients can not be guaranteed.

Incidents of equipment failure or total downtime are a big turn-off for patients and must be prevented as much as is possible or addressed almost immediately. Having a preventive maintenance program is therefore not negotiable. It is not just imperative in extending equipment life span but also an important aspect of delivering excellent customer service.

Simply put, efficient and predictable healthcare services cannot be provided without a reliable equipment management program.

The nature and complexity of the program depend on the size and type of facility, its location, and the resources available. What matters is having a reliable plan that works.

TYPES OF MEDICAL EQUIPMENT MAINTENANCE

The World Health Organization has categorized Medical equipment maintenance divided into two:

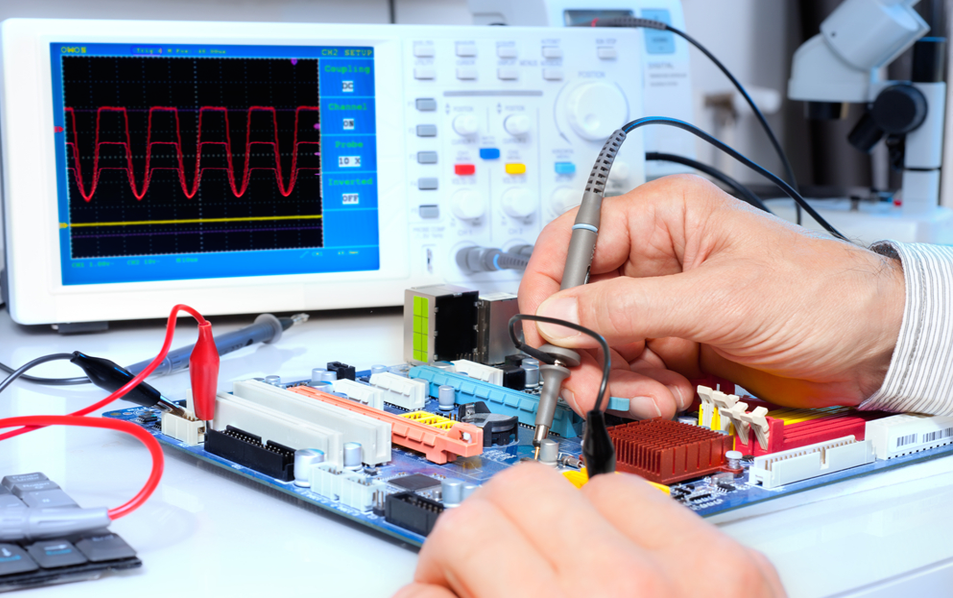

- Inspection and and preventive maintenance (IPM):This includes all scheduled activities that ensure equipment functionality and prevent breakdowns or failures. Performance and safety inspections are straightforward procedures that verify proper functionality and safe use of a device. Preventive maintenance (PM) refers to scheduled activities performed to extend the life of a device and prevent failure (i.e. by calibration, part replacement, lubrication, cleaning, etc). Inspection can be conducted as a stand-alone activity and in conjunction with PM to ensure functionality.

- Corrective maintenance (CM): This is carried out to and it is carried out when equipment failure has occurred or when a device user has reported a problem with the equipment in other to return it to service or full functionality. It involves troubleshooting, identification and repair of what ever fault was identified functionality.

KICK STARTING EQUIPMENT MAINTENANCE PROGRAM

Medpau International Limited offer preventive maintenance plans or contract on request and/or upon the sale of equipment. This way, maintenance is carried but expert Engineers who are dedicated to ensuring the burden is taken off the medical equipment owners, and within an organized system. This way, they can make the most from their investment and have more time to think about their expansion strategies.

More importantly, Medpau International Limited has unlimited technical support from channel partners, global brands, and manufacturers. The constraints hospital or their Engineers could encounter in sourcing replacement parts are abated. Our team of highly responsive Engineers operates within an organized system. They are available and accessible 24/7 and have been trained to deliver excellent services with the utmost professionalism.

The responsibility of ensuring healthcare facilities have functional equipment maintenance plan lies with the Technical Department, but since many hospitals do not have one, the Head Biomedical Engineer can be in charge. This plan should always have inventory of all the medical equipment and scheduled maintenance timetable. There should also be proper documentation after each maintenance session including faults diagnosed and corrective actions taken. This information can identify preventable reoccurring faults or even help in what is called Predictive maintenance, where an Engineer can predict what could probably go wrong and take proactive steps.